Lower Fuel & Operating Costs

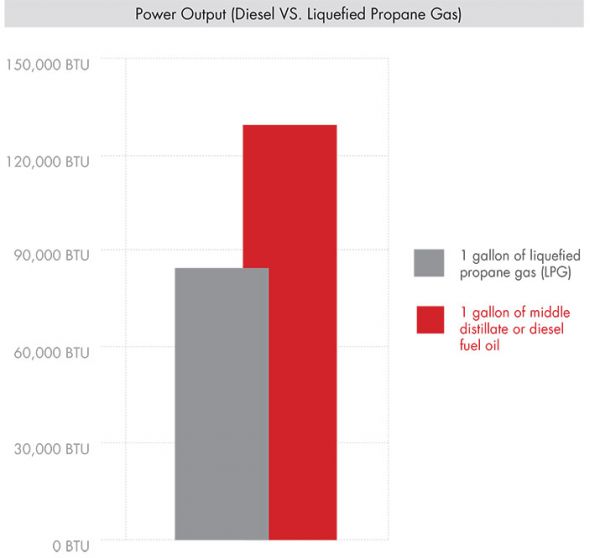

Clean Diesel is high on power — over 50 percent more power than LP gallon-for-gallon. Getting tough jobs done faster is just one of the fuel-saving advantages of Grasshopper diesel-powered equipment, but diesel engines have an advantage in low-load situations as well.

Diesel engines adjust their air-to-fuel ratio depending on how hard they are working. In conditions where the diesel engine is running under a small load or idling, it consumes very little fuel, with an air-fuel ratio at times of 60:1 versus an average of 14.7:1 in gasoline engines.

Air-To-Fuel Ratio*

60:1

14.7:1

*Gasoline consumes four times as much fuel as diesel in low-load situations.

In controlled mowing tests, Grasshopper MaxTorque™ diesel mowers are found to use only half the amount of fuel as equal-powered gasoline models. Feedback from customers using Grasshopper diesel mowers in real-life mowing conditions verifies the controlled findings: Over the course of 1,000 hours, you can save 650 gallons or more of fuel using diesel-powered Grasshopper mowers versus gasoline models of similar power. The fuel savings are even greater versus LP.

How much can you save by making the switch to Grasshopper MaxTorque™ Diesel?

compare fuel costs and emissions.

Where do you plan to fuel your equipment? Will your operators need special permits to refuel their tanks?

A huge advantage with diesel is the availability of diesel fuel at most service stations (and the availability of even cheaper off-road diesel fuel at many other locations) versus the special handling and certification requirements of filling LP or CNG tanks.

Diesel fuel is also a relatively safe fuel because it generally does not ignite unless it is heated. The National Fire Protection Association, on the other hand, tags CNG with the highest hazard ranking for flammability. In the event of a fuel leak, diesel fuel is less likely to ignite than LP or CNG leaks.

While it's possible in some localities to obtain special permits for facilities to store and handle the refueling of LP and CNG gas tanks, more often than not, the equipment owner will have to transport the tanks to a licensed refueling station and will be charged a special handling fee for the services – on top of the fuel charges.

In addition to special handling and service fees, used propane tanks are usually replaced with full tanks, even though the used tank may still contain unburned fuel. The risk of overpaying for propane based on replacement "empty" or "used" tanks at the end of the day is significantly increased if you aren't paying close attention to your fuel consumption rate.

As a byproduct of the crude oil and natural gas refining processes, propane cannot be produced in greater quantity when demand spikes. The price of propane fluctuates greatly depending on inventories and demand. Fuel contracts can stabilize pricing for month-to-month budget purposes, but a contract can actually cost you more when market prices fall below contract prices.

In addition, there are relatively few propane tank refilling stations that are accustomed to the rush-demand of commercial and government mower fleet operations, so operating costs are sure to increase with LP or CNG gas fuels, if for no other reason than the refueling dilemma.